In 1875, the offset printing press was created for printing on tin. In 1904, it was upgraded for printing on paper. Offset printing is a more modern term for lithography. Printed from stone is the definition of lithography. This occurred because limestone, rather of the more costly metal used for making printing plates in the past, was used for the very first printing plates.

Offset Printing

A common printing press method is offset printing, which involves moving ink from a plate to a rubber roller and finally onto a printing surface. Because of its cheap cost and great quality, offset printing (also known as offset lithography) is used for mass manufacturing of custom printed boxes, magazines, and other items. The process of offset printing involves moving a picture from an image plate—often made of aluminium—to a rubber "blanket" and then onto the printing surface. The term "offsetting" describes the process by which the printed image is transferred from the plate to the blanket, therefore the name of the printing technique.

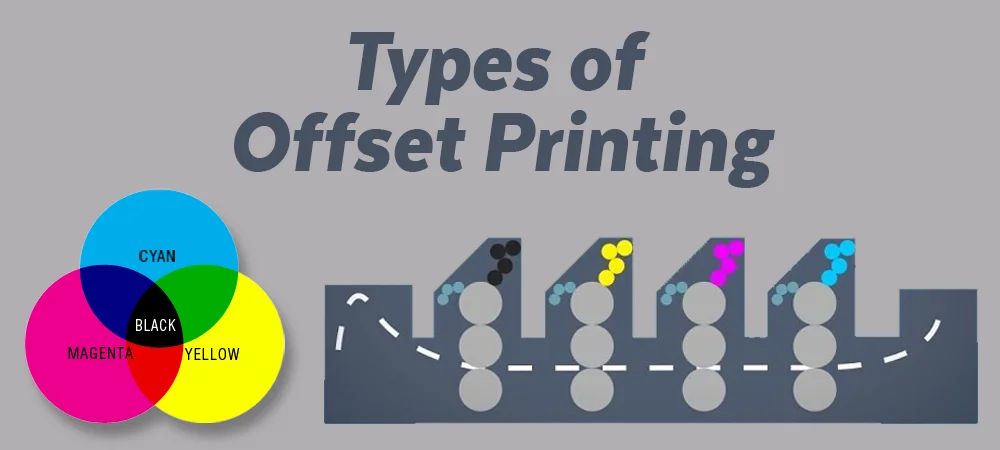

Different Types of Offset Printing

Depending on their needs, businesses turn to various forms of offset printing.

1. Web

With web offset printing, a large continuous sheet of paper is printed on and then cut and separated. For orders of magazines, books, or newspapers in bulk, this offset printing method is perfect.

2. Sheet-fed

Before the printer gets the pages, sheet-fed offset printers trim them. To feed a single sheet of paper into a printer, a sheet feeding machine uses an air jet. Additionally, the devices include with sensors that will turn off the printer in the event that it detects a single sheet to be too thick, indicating that it is still attached to another.

3. Quick-Set

Because it sets fast but dries slowly, quick-set printing equipment may save ink. Manuals, instruction books, and magazines are the perfect candidates for this printing style. In comparison to usual offset printing technologies, they dry much quicker, resulting in a much quicker process. One needs to get themselves with the process of offset printing before choosing the best method to achieve their goals.

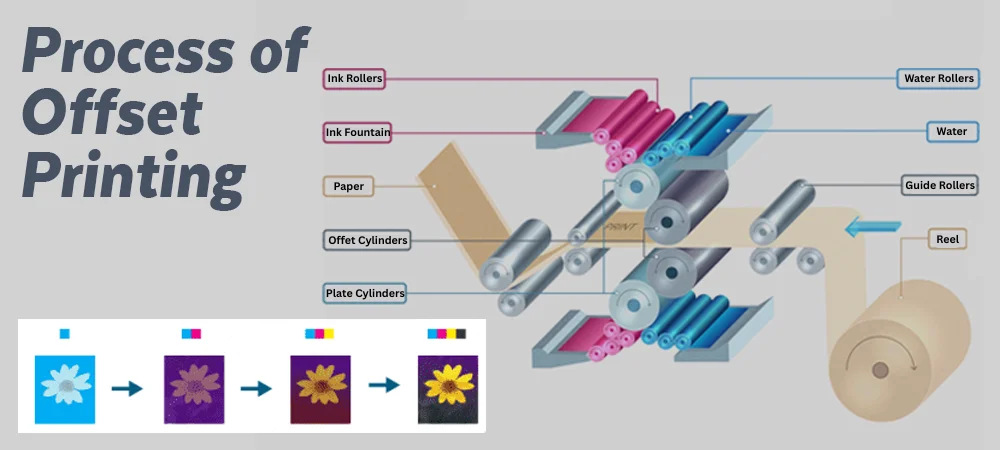

What is the Process of Offset Printing?

The procedure remains the same no matter the printing method that is going to be applied. To understand the process of offset printing, possibly refer to the information provided below.

Preparing

The image that is to be printed must be digitally prepared by designers and operators. This procedure includes the development of various types of the image that highlight CMYK colour groups. The plate cylinder is covered by an aluminium plate that is laser etched with every stage of the image. Operators customize the four colour groups per printer to generate an accurate and vibrant image for the client, as this printing method prints colours one at a time. These changes include for example, the improvement of the intensity of the blue hue and the reduction of the vibrance of the yellows.

Feeding

Offset printing proceeds after employees adjust the printers to the appropriate colour profiles. The process is automated by air nozzles that propel a single sheet of paper into the printers. Modern printers are equipped with detectors that automatically close down the system when they detect that a paper is extremely thick. This results in two sheets being pulled together during the input process. Upon entering the printer, the paper is directed through the printing cylinders to receive ink.

Printing

The ink commences its journey at the plate cylinder and proceeds through a series of rollers and cylinders before reaching the paper. The ink rollers apply ink to the image portions of the print, while the dampening rollers apply water to the non-image parts of the print as the plate cylinder revolves. Water is essential for the clear separation of coloured and non-coloured areas on the print, as it is chemically structured to reject ink. The ink is transferred exclusively to the revolving rubber-wrapped blanket cylinder beneath the plate cylinder as it revolves. The blanket cylinder is the sole inked cylinder that contacts the paper. The ink is fused into position by an impression cylinder that is located beneath the paper. The final product is created by passing the paper through a series of cylinders that are similar in design but contain a variety of coloured dyes.

Drying

The printer places the paper on a stack at the end after it has received the final coat of ink. At this time, the ink remains damp. Anti-set-off powder is sprayed onto the printed papers by a machine to prevent them from adhering to one another or causing ink smudges after printing. Printing personnel then transport printed pages to a guillotine, where they are trimmed. Offset printing frequently generates superior reproductions in comparison to other methods, despite its tendency to induce feelings of anxiety. It is possible to determine the most suitable printing method for a particular task by examining alternative printing methods; digital printing is among the most commonly used.

What is the Difference Between Offset and Digital Printing?

Offset printing uses printing plates and wet ink to produce high-quality prints. The production process is more time-consuming due to the need for multiple setup steps and the requirement for the finished product to be completely dry before it can be completed. That being said, offset printing is the more cost-effective choice for producing a large quantity of a specific design. Contrast this with digital printing (formerly referred to as "copying"). When it comes to digital printing, the end result comes straight from electronic files. The short-run products such as brochures, business cards, or posters are commonly produced using digital printing. When it comes to website content, digital printing is just as good as offset printing in terms of quality. However, offset printing offers a wider variety of ink colours that digital printing currently is unable to match.

Why Offset Printing is Beneficial?

Among the many advantages that offset printing offers, businesses may reap the following rewards:

1. Printing of Superior Quality

The quality of offset printing is unique and unrivalled, according to experts in the field. To get proper printing results, it is necessary for printing operators and customers to establish colour settings per printer.

2. Low-cost Printing

The majority of the cost is incurred by companies during the setup phase, which includes procuring the required metal plates, designing and transferring them onto them, and calibrating the colours. Printing hundreds of copies quickly is a breeze once the printers are configured. The price per print decreases as the quantity requested increases. Offset printing is a good investment because of the quality you get for the amount of prints your purchase.

3. Relatively Fast Processing

Only two steps—preparing the printing plates and waiting for the completed goods to dry—extend the turnaround time. Regardless, when it comes to large-volume assignments, offset printing still beats digital printing.

4. Enduring

Part of what makes printing more eco-friendly is the ink that printers use. If a printing company wants to provide its customers more biodegradable packaging, they may employ ink made from vegetable oil. The plate cylinder's aluminium plate is another factor. Rather of rubbing against rough and possibly abrasive printing medium like wood or cardboard, it contacts the pliable, rubber blanket cylinder, extending its lifespan.

5. Various Material Choices

Experimenting with alternative designs for product packaging is made possible by printing on numerous materials. Any material, surface, or form may be offset printed. For companies that need strong and aesthetically pleasing product packaging, offset printing is a great choice. New packaging data shows that consumers are increasingly favouring paper and cardboard packaging, therefore the strong product packaging is a great way to meet their requests.

Conclusion

The proper packaging, in terms of design, package material, setup, and price, can really make a product stand out. Make sure that the people working on your package design and every step of the process are qualified professionals in the packaging industry. They should be able to take on any task, no matter how complicated, and bring it to life with style and elegance.

Feel free to contact HT Custom Boxes for a no-obligation calculate if you have any questions about offset printing, our printing methods, or the packaging requirements you have. We will look into your product thoroughly to learn about your brand, your desired message, and your ideas for the product's packaging. We provide full-service package design and printing; get in touch with us now to discuss your product packaging needs and find out how we can help.

.webp)