Creating a dieline is one of the most important steps in packaging design. A dieline template shows exactly where your packaging will be cut, folded, and glued. Using a proper dieline ensures your packaging looks professional, works correctly, and avoids mistakes during printing.

Even for beginners, creating a dieline is not difficult if you follow the right steps. This guide explains everything you need to make a dieline from start to finish, including tips, common mistakes, and examples for different packaging types.

Step 1: Choose a Package to Reference

If you are new to packaging dieline design, it is helpful to start by looking at a package similar to what you want to create.

- Carefully unfold the package and lay it flat.

- Examine all panels, flaps, and tabs.

- Take notes of how the package folds and where glue is applied.

Why this matters: Understanding how a real package folds will help you create an accurate dieline template.

Example: If you want to design a folding carton for a small gift box, use an existing box of similar size to guide your measurements and panel layout.

Step 2: Measure Every Part

Accurate measurements are essential for a successful dieline template. Use a ruler or measuring tool to record:

- Width and height of each panel.

- Size of flaps, tabs, and glue areas.

- Depth of folds and any special shapes, like rounded corners or slanted edges.

Tip: Measure twice to make sure your numbers are correct. Even a small mistake can cause the package to not fit together properly.

Extra Advice: If you plan to create multiple sizes of the same package, keep a detailed measurement sheet. This makes it easier to scale your packaging dieline accurately.

Step 3: Create a Flat Layout in Software

Use vector-based software such as Adobe Illustrator, Corel Draw, or Affinity Designer to build your packaging dieline digitally.

- Draw each panel, flap, and fold according to your measurements.

- Use separate layers for cut lines, fold lines, and artwork areas.

- Create a flat dieline template that can later be folded into a 3D package.

Tip: Label each panel and flap clearly. This will help you, your client, or your printer understand how the package will fold.

Extra Tip for Beginners: If you don’t have professional software, free tools like Inkscape or Canva (for simple projects) can also work.

Step 4: Add Fold and Cut Lines

Mark fold and cut lines clearly in your dieline for printing. Use standard color coding:

- Magenta for cut lines – shows exactly where the material will be cut.

- Cyan for fold lines – shows where the package will fold.

- Dotted lines for safe zones – areas where text, logos, or important graphics should not go.

Why this matters: Clear fold and cut lines help printers and designers avoid mistakes, and make assembly easier.

Extra Tip: Keep color coding consistent across all dielines so your printer can follow instructions quickly.

Step 5: Include Glue Areas and Tabs

For packages that require glue:

- Mark all glue areas and tabs clearly.

- Make sure tabs fit together properly without overlapping or leaving gaps.

- Avoid placing important artwork over glue areas.

Example: Cosmetic boxes often have multiple flaps glued together. If glue areas are wrong, the box may not close correctly or look neat.

Tip: Use dashed or hatched patterns to indicate glue areas on your dieline template. This makes instructions clear for printers and manufacturers.

Step 6: Add Bleed and Safe Zones

- Bleed: Extend your artwork slightly beyond the cut line. This prevents unwanted white edges during printing.

- Safe Zone: Keep all important text, logos, and graphics inside this area to prevent accidental cutting.

Beginner Tip: Use a minimum of 3 mm (1/8 inch) for bleed and 6 mm (1/4 inch) for safe zones.

Extra Advice: Even small elements like product weight, barcodes, or regulatory symbols should be inside the safe zone to avoid problems during production.

Step 7: Test with a Paper or Cardboard Model

Before sending your dieline to the printer:

- Print it on paper or cardboard.

- Cut, fold, and assemble the package.

- Check if panels, flaps, and artwork align properly.

Why this matters: A test model allows you to see the package in real life. It helps catch mistakes early, saving time and money.

Pro Tip: Take photos of the mock-up to review and share with clients or team members.

Step 8: Review and Share with Your Printer

- Double-check all measurements, fold lines, and cut lines.

- Confirm the color coding, bleed, and safe zones with your printer.

- Share the dieline template along with artwork files.

Tip: Ask your printer if they need the dieline in a specific format like AI, PDF, or EPS. This ensures compatibility and reduces errors.

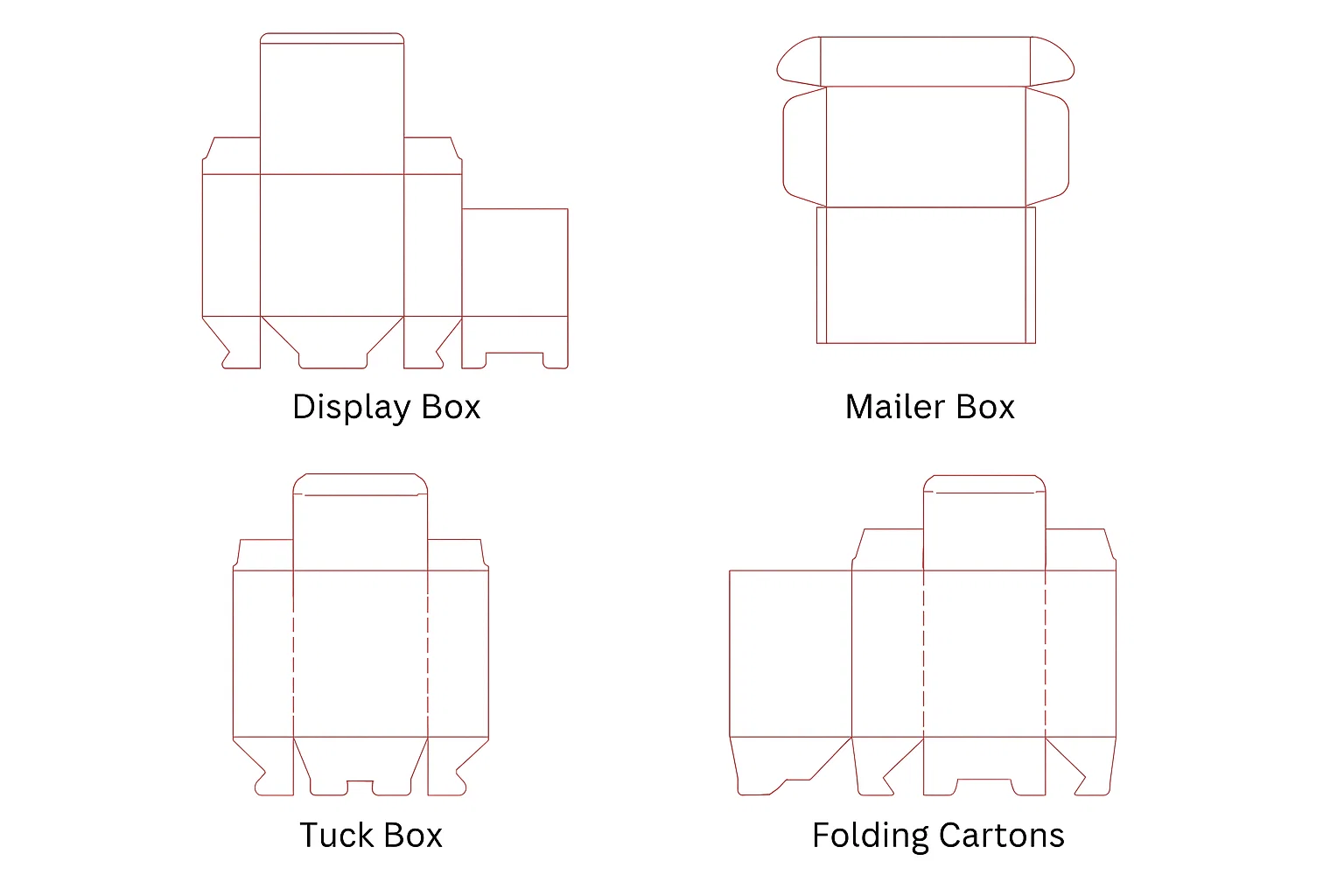

Common Types of Dieline Templates

Different packaging styles require different dieline templates. Here are some of the most common ones:

Display Boxes

Display box dielines are designed to showcase products directly on shelves. They usually have open fronts or windows that make items visible and attractive to customers.

Tuck Boxes

Tuck box dielines feature tuck-in flaps on the top, bottom, or both ends. They are commonly used for products like cosmetics, food, and small retail items because they are easy to assemble and secure.

Folding Cartons

Folding carton dielines are versatile and widely used for packaging lightweight products. They fold flat for shipping and storage, making them cost-effective and eco-friendly.

Mailing Boxes

Mailing box dielines are sturdy designs made for shipping products safely. They usually include double walls or self-locking flaps to protect items during transit.

Common Mistakes to Avoid When Creating a Dieline

1. Misaligned Panels or Flaps

When panels or flaps don’t align properly, the packaging won’t fold or close correctly. This can make the box look unprofessional and may even affect its functionality. Always double-check your panel measurements before finalizing the dieline.

2. Placing Text, Logos, or Graphics Outside the Safe Zone

Anything placed outside the safe zone runs the risk of being cut off during trimming. Keep all important elements like brand logos, product names, and text well inside the safe zone to ensure they remain visible on the final package.

3. Missing or Incorrect Cut and Fold Lines

Cut lines show where the design will be trimmed, while fold lines indicate where the package will be creased. Forgetting or mislabeling these lines confuses the printer and leads to errors in production. Always label them clearly and use standard guidelines.

4. Forgetting Glue Areas

Glue flaps are essential for holding the box together. If you don’t leave proper space for glue areas, your packaging may not stay intact. Mark glue zones clearly on the dieline so they are not accidentally used for design elements.

5. Using the Wrong Units of Measurement

Mixing up units like inches and millimeters can cause major sizing issues during printing. Always confirm your measurements in the correct unit system that matches your printer’s requirements.

Final Thoughts

Creating a dieline may seem complicated, but following these steps will help you make an accurate and professional packaging dieline. A proper dieline template saves time, reduces waste, and ensures your design fits perfectly.

Practicing and testing your dielines for printing will improve your skills and allow you to produce high-quality packaging that looks professional, functions well, and strengthens your brand.

Need help with your packaging dielines? HT Custom Boxes can provide custom solutions to bring your packaging ideas to life.

Frequently Asked Questions

Who Creates a Dieline?

A dieline is usually created by packaging designers or printers to guide the cutting, folding, and assembling of packaging.

How to Make Your Own Dieline?

You can make a dieline by measuring a package, creating a flat layout in design software, and marking cut, fold, and glue areas.

What is the Bleed Line in Dieline?

The bleed line is the outer edge beyond the cut line where artwork extends to avoid white gaps after trimming.

What Color Should Dielines Be?

Standard colors are magenta for cut lines, cyan for fold lines, and other clear codes for safe zones and glue areas.

What Does a Solid Line Indicate on a Dieline?

A solid line on a dieline usually indicates a cut line, showing exactly where the packaging will be trimmed.

Aminah Zaheer

Aminah Zaheer

.webp)