Cardboard is a thick and strong kind of paper that is used to make boxes and many other everyday items. You see it all around you — in cereal boxes, delivery packages, and storage boxes for books or toys. People like using cardboard because it is strong, lightweight, and easy to shape. It’s also good for the environment since it can be recycled.

In this blog, you’ll learn what cardboard is, what it’s made from, how it’s produced, its main types, uses, and why it’s such an important material in the packaging industry.

What Is the Meaning of Cardboard?

Cardboard is a heavy, paper-based material that is thicker and stronger than regular paper. It comes in different forms, but all types are designed to hold, protect, or carry things safely.

The word “cardboard” is commonly used in daily life, but in the packaging industry, it can refer to a few specific materials:

- Paperboard: A thin and smooth type of cardboard used for cereal boxes, tissue boxes, and similar packaging.

- Corrugated Cardboard: Made of three layers, including a wavy middle layer. It’s strong and used for shipping boxes.

- Chipboard: Made from recycled paper and used for light packaging such as product covers or backing boards.

What Is Cardboard Made From?

Most cardboard is made from wood pulp, which comes from trees. The wood is broken into small pieces, turned into a wet pulp, then pressed and dried into strong sheets.

Some types of cardboard are made from recycled paper, which helps reduce waste and saves trees. Used boxes and paper are collected, cleaned, and processed into new cardboard sheets.

Depending on the type, cardboard can be made from:

- One flat layer (like paperboard)

- Three layers (like corrugated cardboard)

- Many recycled layers (like chipboard)

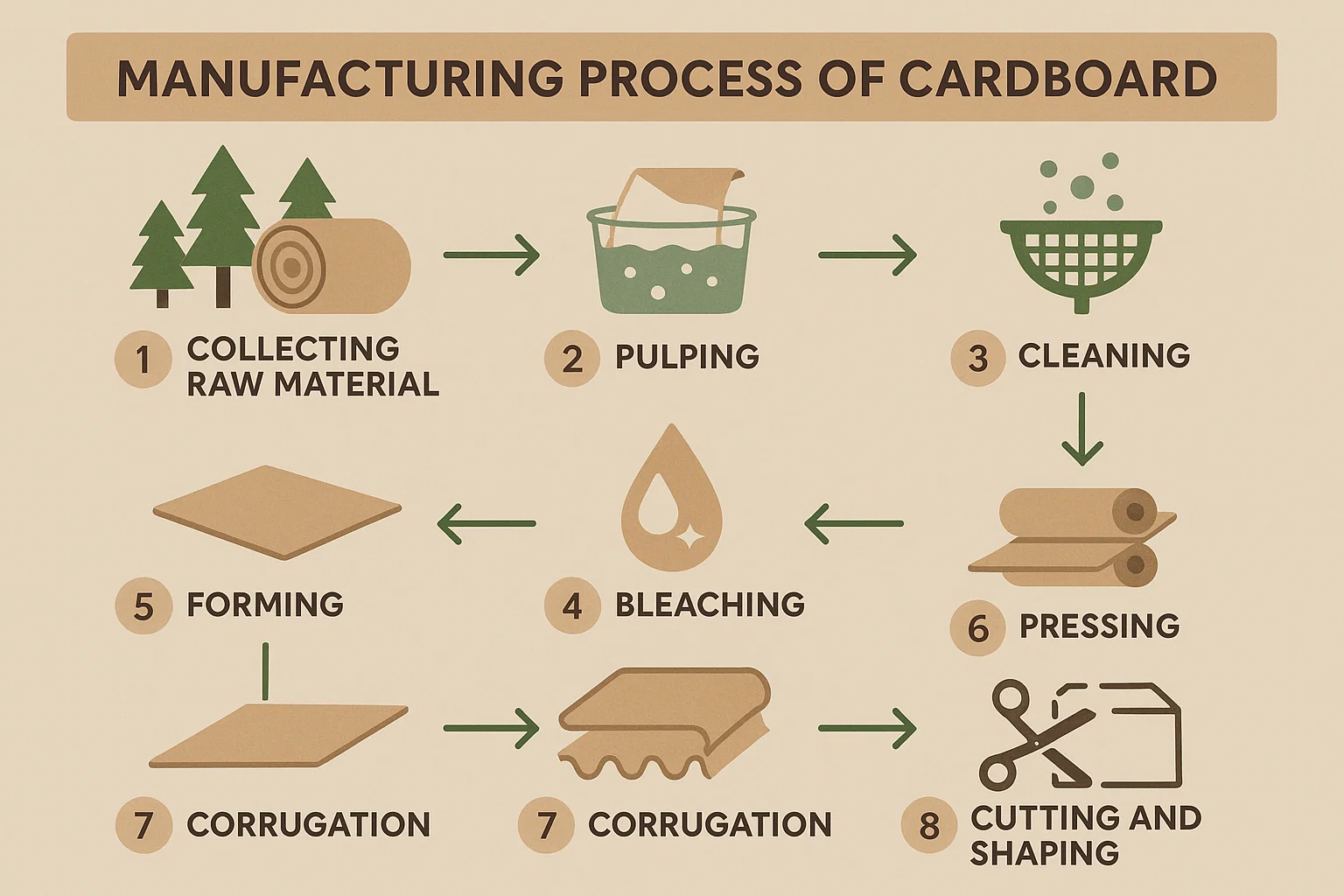

Manufacturing Process of Cardboard

1. Collecting Raw Material

The process starts with collecting raw materials, mainly wood pulp or recycled paper. Many manufacturers now prefer recycled material to reduce waste and save natural resources.

2. Pulping

The raw material is mixed with water and broken down into small fibers to create pulp. This step helps make a smooth and even texture for the cardboard sheets.

3. Cleaning

The pulp is cleaned to remove dirt, ink, or any unwanted particles. Clean pulp ensures that the final cardboard is smooth and free of impurities.

4. Bleaching

If white or light-colored cardboard is needed, the pulp is bleached. This makes the material brighter and more appealing for printing or packaging.

5. Forming

The cleaned pulp is spread onto a moving screen where water drains out. The remaining wet sheet starts to form the base layer of cardboard.

6. Pressing

The wet sheet passes through rollers to remove extra water and make it denser. Pressing also helps the sheet bond firmly, giving it better strength.

7. Corrugation

In this stage, one sheet of paper is pressed between rollers to form flutes (waves). These flutes are glued between flat liners to make corrugated cardboard. The fluted layer adds cushioning and strength.

8. Cutting and Shaping

Finally, the large sheets are cut and shaped according to the required box sizes. They may also be printed or coated depending on the final use.

Types of Cardboard

The types of cardboard vary with the structure, layering, and size of flutes added in between the layers of cardboard sheets to achieve the required level of protection.

Single Wall Cardboard

Single wall cardboard is the most common type used for packaging. It has one layer of fluted (wavy) paper sandwiched between two flat sheets called liners. This structure makes it light but strong enough for most shipping boxes. It is ideal for items that are not too heavy, such as electronics, toys, or food packaging.

Double Wall Cardboard

Double wall cardboard has two layers of fluting and three liners. It offers more strength and protection than single wall cardboard. Because of its solid build, it is often used for heavier products or for stacking boxes on top of each other during transport or storage.

Triple Wall Cardboard

Triple wall cardboard is the strongest type. It has three fluted layers and four liners, making it extremely durable. It can handle very heavy or fragile items and is often used for industrial packaging, furniture, or machinery. It provides excellent protection against crushing and impacts.

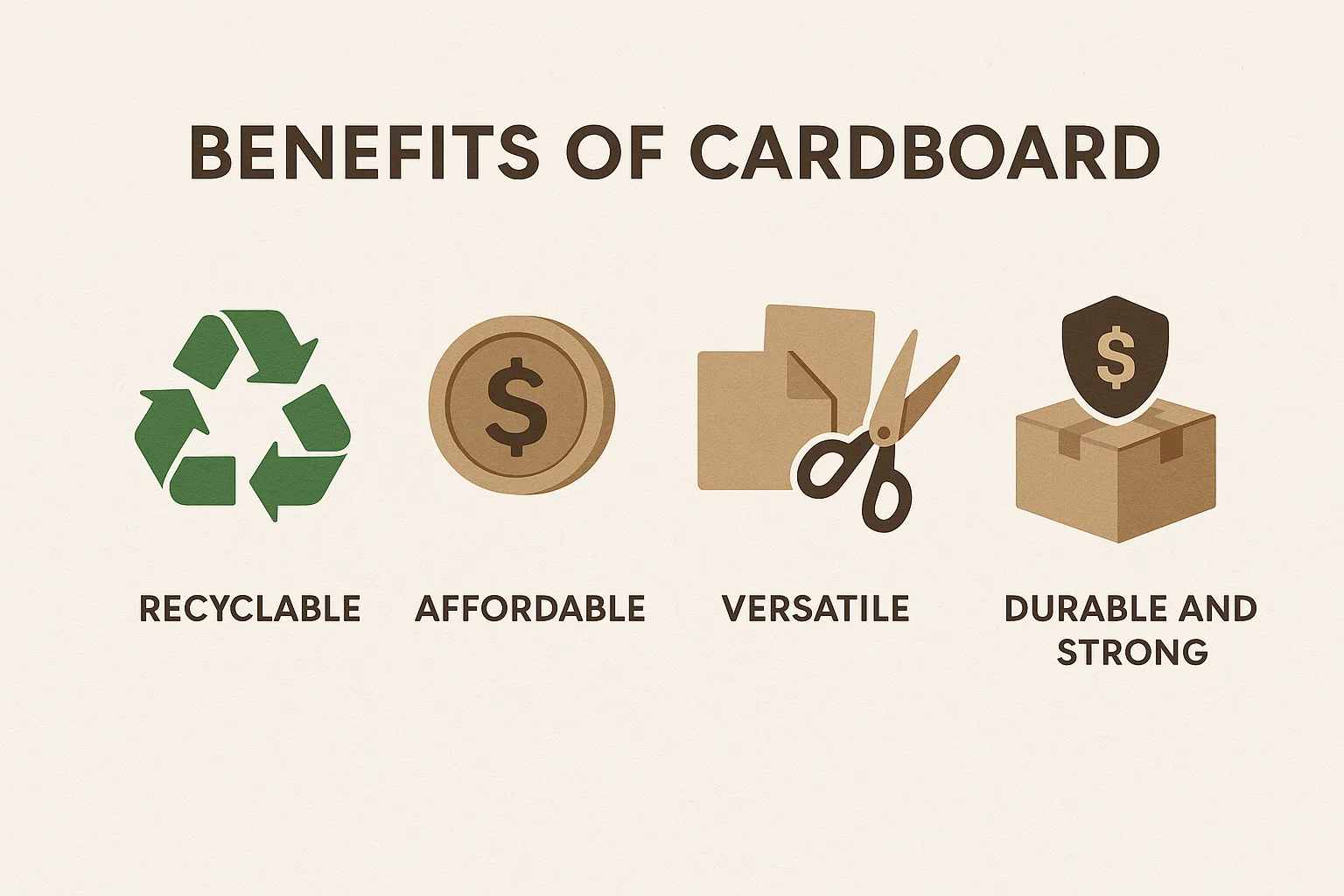

What Are the Benefits of Cardboard?

Cardboard has many good qualities. That’s why it is used in so many ways.

- Recyclable

Cardboard is easy to recycle and can be reused to make new boxes or paper products. This helps reduce waste and protects the environment. - Affordable

It is one of the most cost-effective packaging materials. The raw materials are cheap, and the production process is efficient, making it suitable for small and large businesses. - Versatile

Cardboard can be used for many purposes such as packaging, displays, crafts, and storage. It can be printed, coated, or cut into different shapes to suit various needs. - Durable and Strong

Despite being lightweight, cardboard can hold a good amount of weight. The layered design provides strength and protection, making it reliable for shipping and storing items.

Grades of Cardboard

Cardboard comes in different grades based on the quality and thickness of the material.

- Recycled Grade: Made mostly from reused paper. It is eco-friendly and affordable, best for light packaging.

- Kraft Grade: Made from virgin pulp, it is stronger and more tear-resistant. Often used for heavy-duty boxes.

- White Lined Grade: Has a white outer layer that is ideal for printing and product packaging.

- Test Grade: A mix of recycled materials that offers a balance between strength and cost.

What is Cardboard Used For?

Cardboard is used in many different ways in both industries and everyday life. Its strength, flexibility, and eco-friendly nature make it useful for much more than just packaging. Below are some of the most common and practical uses of cardboard.

1. Shipping and Transportation

Cardboard is widely used for shipping boxes that carry goods safely from one place to another. The corrugated layers protect items from shocks and pressure during transport. From small parcels to large industrial shipments, cardboard plays a key role in keeping products safe.

2. Food Packaging

Many types of food containers are made from cardboard, including cereal boxes, pizza boxes, takeaway trays, and beverage carriers. It helps keep food clean, dry, and fresh. Cardboard is also lightweight, easy to print on, and often recyclable, making it perfect for the food industry.

3. Product Packaging

Cardboard is used to pack clothing, shoes, cosmetics, electronics, and toys. Businesses often print their logos or designs on boxes to create a professional look. Because it can be cut and folded easily, it suits a wide range of product shapes and sizes.

4. Storage and Organization

People use cardboard boxes at home, in schools, and in offices to store books, documents, clothes, and other items. They are lightweight, stackable, and available in many sizes, making them a practical choice for organizing spaces.

5. Display and Promotion

In retail stores, cardboard is used to make display stands, signs, and promotional cutouts. These displays are affordable and easy to move or replace. Businesses like using them because they can be designed and printed in any shape or color to attract attention.

6. School and Craft Projects

Cardboard is a favorite material for art and craft projects. Students use it to create models, posters, and dioramas. Artists and hobbyists also use cardboard for creative designs, sculptures, and handmade items because it is easy to cut and shape.

7. Furniture and Interior Design

Some designers use heavy-duty cardboard to make eco-friendly furniture such as chairs, tables, and shelves. Cardboard furniture is light, strong, and recyclable, making it a sustainable option for temporary or creative setups.

8. Industrial Applications

Cardboard is also used in industries for making protective layers, dividers, and cushioning materials for fragile products. Some factories use thick cardboard sheets as separators between metal, glass, or plastic items to prevent scratching and damage.

9. Advertising and Signage

Printed cardboard boards are used for posters, signs, and event displays. They are affordable, easy to set up, and suitable for both indoor and outdoor short-term use.

10. Eco-Friendly Alternatives

Cardboard is becoming a popular replacement for single-use plastics. Companies now use it to make cups, trays, straws, and other disposable items that are biodegradable and recyclable. This helps reduce plastic waste and supports environmental goals.

Is Cardboard Biodegradable or Eco Friendly?

Yes, cardboard is biodegradable because it is made from natural plant fibers. It breaks down easily when exposed to moisture, air, and microorganisms. Usually, it takes around two to three months to decompose in normal conditions. However, if it is coated with plastic or wax, it may take longer to break down. Choosing uncoated or recyclable cardboard is the best option for the environment.

How Cardboard Helps the Packaging Industry

The packaging industry uses cardboard more than any other material. It is helpful in many ways.

- Keeps Products Safe

Cardboard boxes protect products from damage, dust, or water. This is very important when things are being shipped or stored. - Supports Branding

Cardboards can be printed with company logos, colors, and messages. This helps businesses show off their brand and attract buyers. - Reduces Cost

Since cardboard is light and easy to make, it helps save money on packing and shipping. - Helps E-Commerce

Online shopping is growing fast. Every product that is ordered online needs a safe, strong box. Cardboard is the best choice for this. - Better for the Environment

Today, many people care about the planet. Cardboard is recyclable and biodegradable, so it is better than plastic for packaging.

Get the Best Cardboard Boxes from HT Custom Boxes

Cardboard is an amazing material. It is strong, light, low-cost, and eco-friendly. It is used in shipping, food packaging, storage, and more. It helps companies protect their products and promote their brand. If your business needs custom cardboard boxes that are durable, well-designed, and good for the environment, HT Custom Boxes is the right place to go. We offer high-quality cardboard packaging in many sizes, shapes, and designs to fit your product. Whether you need plain shipping boxes or printed retail boxes, we can help you create the perfect solution for your brand.

Choose HT Custom Boxes for packaging that’s smart, simple, and strong.

Frequently Asked Questions About Cardboard

1. What is cardboard made of?

Cardboard is made from wood pulp or recycled paper. The fibers are mixed with water to form a pulp, then pressed and dried into sheets. Depending on the type, cardboard may have one layer (paperboard) or several layers with a fluted middle (corrugated cardboard).

2. Is cardboard the same as paperboard?

Not exactly. Paperboard is thinner and used for items like cereal boxes, while cardboard is thicker and stronger. Corrugated cardboard, which has a wavy layer inside, is the most common type used for shipping boxes.

3. Is cardboard recyclable?

Yes, cardboard is one of the most recyclable materials. It can be reused to make new boxes, paper, or other cardboard products. However, cardboard that is coated with wax or plastic should be separated, as it’s harder to recycle.

4. Is cardboard biodegradable?

Yes, cardboard is biodegradable because it’s made from natural fibers. It usually breaks down within a few months when exposed to air, moisture, and microorganisms. Coated or laminated cardboard may take longer to decompose.

5. What are the main types of cardboard?

The main types are:

Single Wall Cardboard: One fluted layer between two flat sheets.

Double Wall Cardboard: Two fluted layers and three liners for extra strength.

Triple Wall Cardboard: Three fluted layers and four liners for heavy-duty packaging.

6. What is cardboard used for besides packaging?

Cardboard is used in many areas beyond packaging — such as furniture design, art and crafts, advertising displays, storage boxes, and eco-friendly products like cups and trays. It’s valued for being strong, lightweight, and recyclable.

7. Why is cardboard good for the environment?

Cardboard is made from renewable materials and is fully recyclable. It reduces the need for plastic packaging and helps minimize waste. Many manufacturers now use recycled cardboard to further lower environmental impact.

8. How strong is cardboard?

Cardboard strength depends on its type and thickness. Corrugated cardboard, especially double or triple wall, is very strong and can hold heavy products without tearing or crushing.

9. Is cardboard waterproof?

Standard cardboard is not waterproof. When exposed to water, it can absorb moisture, weaken, and lose its shape. However, special types of cardboard are treated with wax or a thin plastic coating to make them water-resistant, which helps protect products from humidity or light rain.

10. Can cardboard get wet?

Yes, cardboard can get wet, but it may soften or break apart after soaking up moisture. If you need boxes for damp or outdoor conditions, use coated or laminated cardboard that resists water damage.

11. Who invented corrugated cardboard?

Corrugated cardboard was invented in the 19th century. The first patent for corrugated paper was granted in 1856 in England, and it was later developed into the packaging material we use today for shipping and storage.

Aminah Zaheer

Aminah Zaheer

.webp)